Portable saws and table-top machines

| Working Process: | For sizing, trimming and splitting. |

| Workpiece Materials: | Softwood and hardwood, chipboard and fibre materials (MDF, HDF etc.), without coat-ing, with plastic coating, with veneer, glulam, plywood, duroplastics, thermoplastics, solid surface materials (Corian, Varicor etc.), compound materials (HPL, Trespa etc.), non-ferrous metals (aluminium, copper etc.). |

| Machines | Portable saws, trimming, mitre-joint machines, table saws and radial arm cross cut, light sizing saws. |

| Types Of Application: | For cutting along and across grain, trimming and mitre cut. |

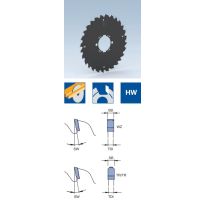

| Tooth Shapes: |  |

Teeth Shape |

Machine | Area Of Application |

| Square Teeth | Portable saws | Solid Wood |

| Alternative top bevel teeth – positive |

Pull push saw, table and radial arm cross cut saws, light sizing saws. |

Uncoated, plastic coated, veneered wood derived materials. Plywood, multiplex plywood. Composite/laminated materials. |

| Alternative top bevel teeth – negative |

Trimming-, pull push saw, table saws and radial arm cross cut saws. |

Solid wood across grain. Plastic hollow wall profiles. Non-ferrous metals – extruded profiles and pipes. |

| Flat/trapezoidal teeth – positive |

Portable saws, pull push saw, table saws and radial arm cross cut saws, light sizing saws. |

Uncoated wood derived materials, plastic coated, veneered. Non-ferrous metals – extruded profiles and pipes. NE-metals. AI-PU sandwich panels. Plastic hollow wall profiles. Plastic polymers (Corian, Varicor etc.). |

| Flat/trapezoidal teeth – negative |

Portable saws, trimming-, mitre saws, table saws and radial arm cross cut saws. |

Non-ferrous metals – extruded profiles/pipes. Plastic hollow wall profiles. AI-PU sandwich panels. |

| Alternative flat tooth with bevel |

Portable saws, trimming-, mitre saws, table saws and radial arm cross cut saws, light sizing saws. |

Flat and angle steel, steel plates, pipes, profiles, sandwich panels, composite materials. |

Number of teeth Tooth pitch Cut quality

Low ~ 25 – 50 mm For coarse cuts.

Medium ~ 14 – 25 mm For good cutting quality.

High ~ 9 – 14 mm For clean cuts to a very high quality.

The saw cut quality is determined by the correct choice of the tooth shape and by the

distance between the teeth. The distance between the teeth is determined by the

tooth pitch.

-

Sizing in finish cut quality Excellent - GlossCut

Sizing in finish cut quality Excellent - GlossCutStarting at $139.85

-

Universal sizing Circular sawblades TR for saw benches

Universal sizing Circular sawblades TR for saw benchesStarting at $104.05

-

Cutting facade panels Excellent Circular sawblade DP design

Cutting facade panels Excellent Circular sawblade DP designStarting at $10,000.00